Bruchsaler Farbenfabrik new calendar for 2021.

Each month we’ll focus on one of the predominant colours which make up the vibrant Bruchsaler Farben pallet. You may choose to download the monthly calendar or just the picture. Feel free to use it for decorating your office or as screensaver...

The shovels with different colours symbolize the intention of the entire calendar by displaying a cross section of the monochrome colours produced by our company. The following calendar pages each represent the colour spectrum of our world, one predominant colour at a time. Enjoy the variety of scenes from the colorful world of Bruchsaler Farbenfabrik.

1st quarter

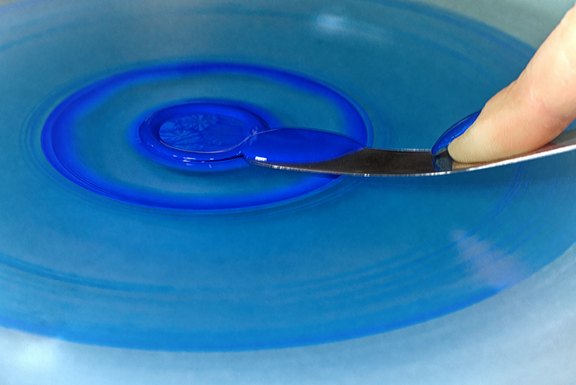

The pan grinder is a very old mixing technique. It has a very long tradition in the production of pigment blends. The term "to rumble" is still a quality term for very intimately mixed compositions where the colours of the individual raw materials will not be visible in the final product. Especially with blue and green blends, this complex process delivers top quality pigments to the needs of our customers.

The chemical production of colour pigments is a vital part of the colourful world of Bruchsaler Farbenfabrik. This picture shows a mixing tank with the agitator running during the precipitation reaction for a bismuth vanadate pigment. The rotating movement of the agitator was captured in a yellow suspension by using a strobe flash.

Another look into the chemical production of pigments. In the now closed drying plant for molybdenum red pigment, a view of a belt dryer with its fans, in which the pigment is dried before grinding.

2nd quarter

Bruchsaler Farbenfabrik still has a collection of original sample bottles with ground glass stoppers. This packing was used until the middle of the last century for retaining samples of pigments both as raw materials and as finished products.

Another view of the pan grinder first seen in January. Scrapers are attached to the heavy, rotating stone wheels to guide the raw material again and again into the trough, where they are finely ground up by strong shear forces. Here it can still be seen that white pigment is also added to the green pigment at this stage of production. The individual colors will not be seen in the final pigment.

As outlined in February, the pigment must be dehydrated and washed free of residues of soluble salts that would interfere with a paint. For this purpose, water flows onto the pigment layer on the drum filter, and then absorbed by the pigment coating into the interior of the drum filter by a vacuum. This way, the salts are washed out and the water content of the pigment layer is reduced at the same time. The images are from the production of bismuth vanadate and molybdate red.

3rd quarter

The "Muller" or plate mulling machine is one of the tools for testing pigments in paints. According to precisely defined conditions, the pigment is incorporated into a paint system via counter-rotating glass panes and distributed as finely as possible in a paint system. This test lacquer is then drawn down onto a card with a specified thickness and then optically measured for its color values.

Pan grinders (see January and May) offer many worthwhile properties. Here we see spring-mounted scraper paddles which ensure that the pigments are repeatedly fed from the edges of the trough to the stone wheels and thus to the further mixing. A mixing process lasts several hours during "rolling" until the first samples can be reviewed. Only after this initial stage can fine tuning begin.

A crank mechanism for lifting the hood of the pan mill is shown. Well lubricated with grease, it cannot deny that it is being used on a piece of equipment for blue pigment blends. Because of the very labor intensive cleaning efforts required, each different color group uses a specific mill.

4th quarter

Without precise measuring of our raw materials; good results cannot be achieved in either chemical production or the manufacture of pigment blends. The picture of a shovel on a scale symbolizes this delicate balance.

One of the relics from bygone times! This "lock" belongs to a barrel hoop with which so-called wooden tubs made of oak are held together. In the past, the pigments were both chemically produced in these and stored before drying. Inside, wooden cross-bar agitators turned. Today stainless steel containers are used for this. You can still see some of these "dinosaurs" in a decommissioned area of our plant.

The hills of pigments shown symbolize the variety of color nuances that we were able to achieve with the molybdate red pigments that were manufactured up until a few years ago, by varying the reaction conditions. Over our long history a full spectrum was created from bright orange to dark red based on the same basic chemical structure. Today, these color variations are produced and sold using environmentally friendly raw materials.